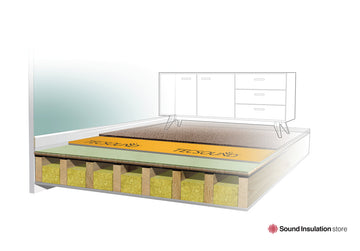

Uplift the existing floorboard / chipboard floor to expose the joists and cavity. Clear the cavity and install 100mm RWA45 Rockwool into the cavity at the bottom leaving an airgap at the top of the cavity. Friction fit the insulation tight within the cavity and infill any small gaps with insulation.

Ensure the existing joists are 400mm centres or less with good structural integrity. Install the dB RD Flanking strip around the perimeter of the room vertically up the wall. Install the dB Panel 37 directly to the joists, push it tight to the perimeter strip around each room. Lay the dB Panel 37 brick bond pattern off setting the joints. Ensure the joints of the panel land on a joist, noggins may need to be installed to ensure this. Use dB Panel PVA adhesive between the tongue and groove joints. Do NOT mechanically the dB panel to the sub floor, this is a floating floor treatment. The dB RD flanking strip can then be cut flush. It can be returned over the top of the floor under the skirt and cut at this point.

For additional mass install Tecsound 100 over the dB Panel 37. Cover the entire floor and take the tecsound tight to the wall. Bit joint the rolls where they meet. The Tecsound can be glued down if necessary using the self adhesive version.Your desired floor finish can then be installed onto the chipboard surface. Check with your floor manufacturer on installation instructions over acoustic flooring.

.

Important Information

Sound Insulation Store are specialists in acoustics and sound insulation. All guidance, system information and predicted performance figures are provided for general assistance only.

It is the customer’s responsibility to ensure that the existing structure is suitable and compatible with any proposed sound insulation system. Where required, customers must seek advice from a structural engineer, building control, or another appropriately qualified professional.

Customers must also confirm whether their project requires specific fire resistance, structural, or regulatory compliance measures. Any fire, structural, or regulatory approval must be obtained independently from a competent specialist.

Sound Insulation Store has worked with NCPL to produce Insul prediction graphs and holds site test data on our Part E systems. These figures are intended as guidance only.

Actual on-site performance will vary depending on the condition and construction of the existing building, flanking transmission routes,installation quality, and any unforeseen site variables.

No performance level can be guaranteed unless independently tested on site after installation.